Water & Sewer

Shaw has considerable expertise in the construction of water and sewer infrastructure having constructed numerous pump stations, pipelines and water treatment plants.

Shaw can provide design, construction and commissioning for all water and sewer infrastructure.

Recent Projects

Project Profile

Water Main Scheme

Ringarooma Valley

Task

Ringarooma, Legerwood, Branxholm and Derby have operated independently and historically had variable water quality, currently with all four towns on permanent boil water alerts issued by the Department of Health and Human Services (DHHS).

Shaw Contracting was engaged by TasWater to install over 30km of water main, as well as a booster pump station to connect and service the four townships with a safe, healthy and reliable water supply, in line with national drinking water standards.

Challenges

Construction of the pipeline included:

- Working in the confines of a road reserve under a single-lane closure traffic management configuration

- Bridge crossings in Ringarooma and Branxholm

- Multiple underground horizontal bores using trenchless technology, including two pipes in parallel under the Ringarooma River in Derby

- Pressure reducing valve (PRV) configuration and installation

- Excavation of over 2,000m3 of rock

- Multiple design alternatives

- Pressure testing pipe in sections up to 10km long

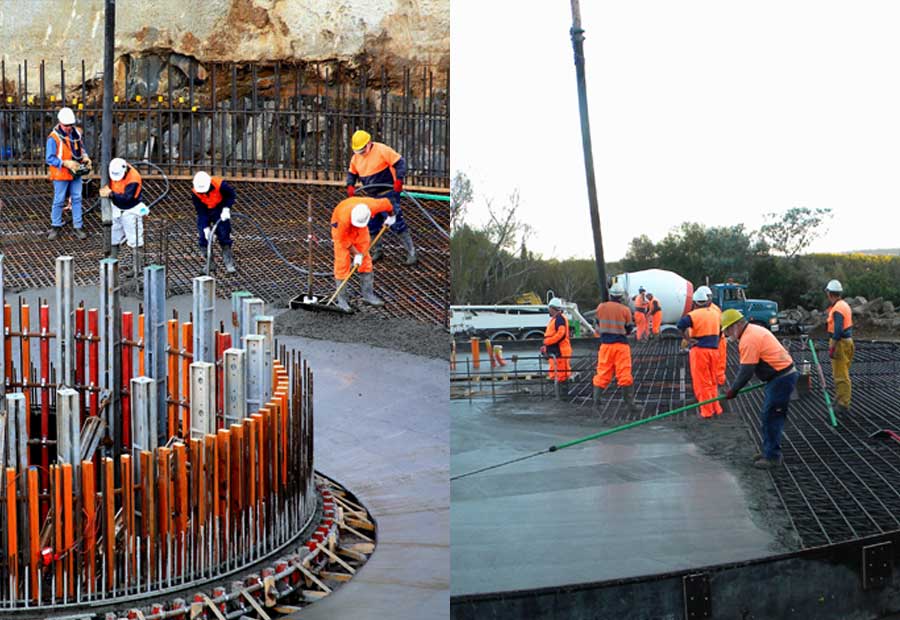

Construction of the booster pump station included:

- Construction of load bearing concrete foundation

- Installation of pre-cast concrete walls and roof

- Construction of generator housing

- Pumps, generator and electrical installation

This project was completed in time for the new Tasmanian Diary Products powdered milk factory to dispose of waste materials into the sewer system. This was a critical outcome of the project from Cradle Mountain Water’s perspective as significant penalties were associated with the Trade Waste Agreement not being achieved.

Outcome

The project was efficaciously delivered to all stakeholders as part of TasWater’s goal to remedy the permanent boil water alerts in the north-east of Tasmania. Employing the diverse skill set of Shaw Contracting’s personnel, the project was delivered to the highest standard both on budget and to schedule.

“Shaw demonstrated a high level of professionalism in the delivery of the Ringarooma Pipeline and Booster Pump Station Project.”

Project Profile

Sewer Reconstruction

Smithton

Task

Shaw Contracting was awarded the $2.7 million dollar contract from Cradle Mountain Water to upgrade the existing M3 Sewer Main in Smithton. The project involved the installation of 1.8km of new gravity sewer main up to 525mm in Dia at depths of up to 4.8 metres.

Challenges

The project timeframe for this contract was extremely tight with only a 4 day tender period, commencement within 3 weeks and construction period of 10 weeks. Shaw Contracting identified early target pipe installation quantities and decided to employee a two team process working on either end of the project. Target pipe installation quantities were achieved and the final connection was completed some 7 days early.

Other challenges included the significant depth of the pipe to be installed including up to 4.8m deep in residential streets and also up to 4.0m deep on Nelson Street, a main arterial road into Smithton. This process was developed early in consultation with CMW to undertake all works using shoring boxes, and single lane closures on the roads to minimise risk and disruption to workers, pedestrians and motorists throughout the project.

During construction another challenge was identified, being that the new pipeline went straight through the redundant Smithton Refuse Disposal site located along the Duck River. This issue caused some minor delays but with the assistance of environmental consultants and working closely with the EPA all issues were resolved in a timely manner and allowed works to proceed.

Outcome

This project was completed in time for the new Tasmanian Diary Products powdered milk factory to dispose of waste materials into the sewer system. This was a critical outcome of the project from Cradle Mountain Water’s perspective as significant penalties were associated with the Trade Waste Agreement not being achieved.

“CMW would like to express their appreciation to the project team of Shaw Contracting for delivering the project on time and on budget."

Project Profile

Pumping Station & Overflow Tanks

Taroona

Task

Due to the old and failing treatment plant needing to be upgraded,Taswater awarded Shaw Contracting to construct the following:

The construction of a new underground sewerage pumping station and associated pipe works including new electrical switchboard.

Demolition of the existing waste water treatment plant and all associated infrastructure.

Installation of a new fibreglass underground overflow storage system

Challenges

The Existing waste water treatment plant is located on steep terrain with limited access which gave for the following challenges:

- Access to site was steep and inaccessible to large plant and machinery.

- To keep the existing treatment plant operational whilst constructing the new pumping station.

- Large deep excavation was required in a very restricted area with existing services in close proximity.

- Due to rock being encountered, sheet pile shoring was not an option so trench shields/benching was used.

- Due to delays on delivery of the overflow tanks, the site had to be maintained and existing excavations protected.

Outcome

The commissioning of the new pump station was critical to allow for the completion of the remaining project, this was done on time and to the complete satisfaction of Taswater.

After delays on the delivery of the overflow tanks, the remainder of the works were completed with minimal disruption to the existing services and nearby residents/business owners.

“A challenging project that needed detailed planning to ensure best outcomes.”

Project Profile

SPS Upgrade

Torrens St, Richmond

Task

The Torrens Street SPS is one of three Sewer Pump Stations in Richmond. It is located next to the Coal River and services approximately 300 properties. Two of the key issues were the deficiency of emergency storage capacity and overflow mitigation. TasWater identified this SPS as high risk based on its condition and performance.

Torrens St SPS had no dedicated overflow discharge point. Overflows occured through the lowest maintenance hole on the eastern side of the Coal River, which then spilt into the Coal River and then entered Pittwater Bay downstream.

Due to high value aquaculture industries Pittwater Bay is considered high sensitivity receiving environment, which stipulates eight hours Average Dry Weather Flow (ADWF) emergency storage capacity.

The existing pumps were undersized as they did not exceed Peak Wet Weather Flow (PWWF) according to TasWater’s design standards.

The wet well itself was in relatively good condition apart from corrosion at the roof. As such TasWater’s plan was to retain the current wet well and merely refurbish the SPS. The current inlet structure used

to function as a wet well for the previous pump station. Modification works such as benching and upsizing of the inlet pipe to the existing SPS were required to achieve compliance and reduce current maintenance activities. The original switchboard did not comply with TasWater’s standards and required replacement.

The original rising main between the SPS and the Sewage Treatment Plant (STP) was approximately 1.3km long with the first 280m being sized at 80mm and the remainder at 100mm. It required replacement with a larger diameter pipe. It crosses Page’s Creek, a small side arm of the Coal River, on Commercial Rd approximately 300 m before the STP. In the present configuration, a separate rising main originating from Bilney St SPS joins into Torrens St rising main at the STP.

Challenges

One of the major challenges on this project was the construction of a temporary pump station directly adjacent to the existing and within the coal river flood zone.

This was achieved by bypassing the existing gravity mains into a poly holding tank and utilising the original pumps to deliver the sewage through the original rising main.

Outcome

The new pump station was successfully commissioned and the temporary PS removed ensuring there is adequate pumping and storage capacity to eliminate any potential over spills into the adjacent waterways

Project Profile

Tolosa Water Supply Upgrade

Ancillary Works

Task

TasWater constructed two 20ML treated water tanks in Tolosa Street, Glenorchy to replace the Tolosa Dam which is to be decommissioned due to significant dam safety and water quality issues.

The project was to construct the ancillary works required for operation of the new Tolosa infrastructure system. The ancillary works include the following supply, install, commissioning of:

- a pump station including electrical works and new switchboards.

- 559 dia MSCL inlet and outlet pipe works including flow meter pit.

- a Pressure Reducing Valve (PRV) station and associated pipeworks

- Demolition of existing infrastructure inc asbestos lined pipework’s and various buildings.

Challenges

One of the major challenges on this project was the construction of the new inlet and outlet pipework’s through Tolosa st,this required excavating the west bound lane of tolosa street to 2.4 metres deep whilst still ensuring access to road users and adjacent residents.

Outcome

The new pumps station and pipework’s were successfully completed allowing TasWater to progress the decommissioning of the existing and failing infrastructure

Project Profile

Queechy Pump Station

Queechy Road

Task

For various historical reasons Launceston currently have five wastewater treatment facilities. Four of these are located within the city and suburbs and existing treatment plants have been designed to meet the effluent standards that were introduced in 1974. Council considered it more economical to decommission some of the smaller treatment facilities and invest in upgrading one or two major treatment facilities. Some investment in pipelines and other infrastructure was also necessary to redirect sewage to the upgraded treatment facilities.

The pump station on Queechy Road was built 45 years ago and overflows during heavy rain. During these overflows odours impact the surrounding residential area. Shaw Contracting was contracted to carry out the $5 million upgrade to the Queechy Pump Station.

Shaw Contracting developed a new pump structure, including a storage tank on the existing site. Inside the main storage tank, which will be used only for overflow, is a six-metre wet well which will handle the day-to-day operations. When that tank reaches capacity it will overflow into the larger outer tank.

Situated in a heavy suburban residential area of Launceston, the pump station is designed to be as unobtrusive as possible. While currently quite visible to the road, the new facility has been designed to blend in with the surrounds and ultimately form a landscaped link to nearby parklands.

Challenges

One of the major challenges with the Queechy Road facility is the size of the site. With the existing pump station still operational, excavation, concreting and heavy lifting equipment had to be managed strategically to ensure smooth construction.

Shaw knew that the material excavated could be reused on the job, but there was a large amount of rock on the site. Not wanting to break up the existing rock and with a number of new sub divisions in the area Shaw was able to attract plenty of clean material from these sites. Shaw then put all excess rock in the nearby creek, which helps with erosion problems.

Outcome

Completed in late July 2010, the new system has ensured better odour management and enhanced environmental benefits. The area, which will be open to the public, has been landscaped and floodlit, and has become a feature of the surrounding area in stark contrast to the former structure. When decommissioned the replaced building will be demolished and used as landfill on the site. The ultimate test for the Queechy Road site is that nobody will know it is doing its job.

"The ultimate test for Queechy Road pumping station is that nobody will know its doing its job."